Services

Environmental

A partial list of our “in-house”, up-to-date, environmental test equipment includes the following:

- Five Single-stage Thermal Shock Chambers

- One Double-stage Thermal Shock Chamber

- One Three-stage Thermal Shock Chamber

- Five Humidity Temperature Cycling Chambers

- Air-to-Air Thermal Shock Chamber (PTL-TSC-1)

- Liquid-to-Liquid Thermal Shock Chamber

- One Impulse Shock Test System

- Three Vibration Test Systems, including Sine, Random, and Sine with Random

- More than twenty Laboratory Ovens

Our multi-million dollar inventory of Environmental, Measuring, and Test equipment allows us to offer our customers expedited testing services and rapid turn-around to meet their urgent requirements in the following areas:

- Corrosion

- Electrochemical Migration Resistance

- Flammability (UL 94)

- Fungus Resistance (ASTM G21, IPC-TM-650 2.6.1 & 2.6.1.1, Mil-STD-810 Method 508)

- Hydrolytic Stability

- Lead-free (Pb-free) Testing

- Moisture and Insulation Resistance

- Outgassing / Outgas Testing (ASTM E595, ASTM E 595, NASA SP-R-0022A, ECSS-Q-ST-70-02, IPC-TM-650 2.6.4)

- Outgassing / Outgas Testing – Weight Loss Method (AMAT 0250-70699 for Cleanroom Packaging Materials)

- Outgassing Kinetics / Contamination Outgassing Characteristics (ASTM E1559)

- Oxygen Index (ASTM D2863)

- Salt Fog, Salt Spray (ASTM B117, ATM A967 Practice C, MIL-STD-810 Method 509)

- Surface Insulation Resistance (SIR)

- Steam Aging

- Temperature/Humidity Cycling

- Thermal Stress

- Thermal Shock and Temperature Cycling

- Total Mass Loss (TML) and Collected Volatile Condensable Materials (CVCM) from Outgassing in a Vacuum Environment

- Vibration and Shock

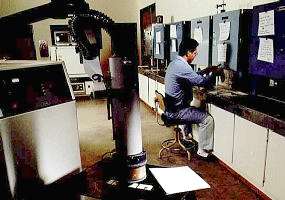

A view of our Thermal Shock area featuring three-stage, two-stage, and single-stage thermal shock chambers. All chambers are equipped with LN2, provided from a single high capacity storage tank. Also pictured are precision temperature forcing systems for small sample testing.

A variety of large capacity precision temperature/humidity chambers provide us with the capability of processing a large number of samples simultaneously. All chambers feature multi-stage microprocessor programming and continuous chart recording of temperature, humidity, number of cycles, duration of cycles, etc.

Several bench top ovens being used in a long-term heat aging test of plastic materials. At the time this photo was taken, the pictured ovens had been in continuous operation for two years at the required test temperatures.