What’s New

What’s New

Celebrating 40 Years of Excellence at Pacific Testing Laboratories

Honoring Four Decades of Trusted Service

Dear Valued Customers,

We are proud to announce that Pacific Testing Laboratories is celebrating its 40th anniversary this year. Since 1985, we’ve been dedicated to delivering high-quality materials testing services, and this milestone reflects our ongoing commitment to precision, reliability, and customer satisfaction.

Over the past four decades, we’ve had the privilege of supporting industries across the world, helping our partners ensure safety, quality, and compliance. This achievement wouldn’t be possible without your continued trust and collaboration.As we look to the future, we remain focused on innovation and excellence in everything we do. Thank you for being a part of our journey.

Warm regards,

The Pacific Testing Laboratories Team

Jet Propulsion Laboratory (JPL) Approval

We are excited to announce that Pacific Testing Laboratories (PTL) has been reapproved for inclusion in Jet Propulsion Laboratory’s (JPL) Approved Supplier List (ASL). PTL continues to provide essential services to the aerospace industry, including PCB/PWB coupon testing, metallography, thermal analysis, and ASTM E595 outgas testing.

We are excited to announce that Pacific Testing Laboratories (PTL) has been reapproved for inclusion in Jet Propulsion Laboratory’s (JPL) Approved Supplier List (ASL). PTL continues to provide essential services to the aerospace industry, including PCB/PWB coupon testing, metallography, thermal analysis, and ASTM E595 outgas testing.

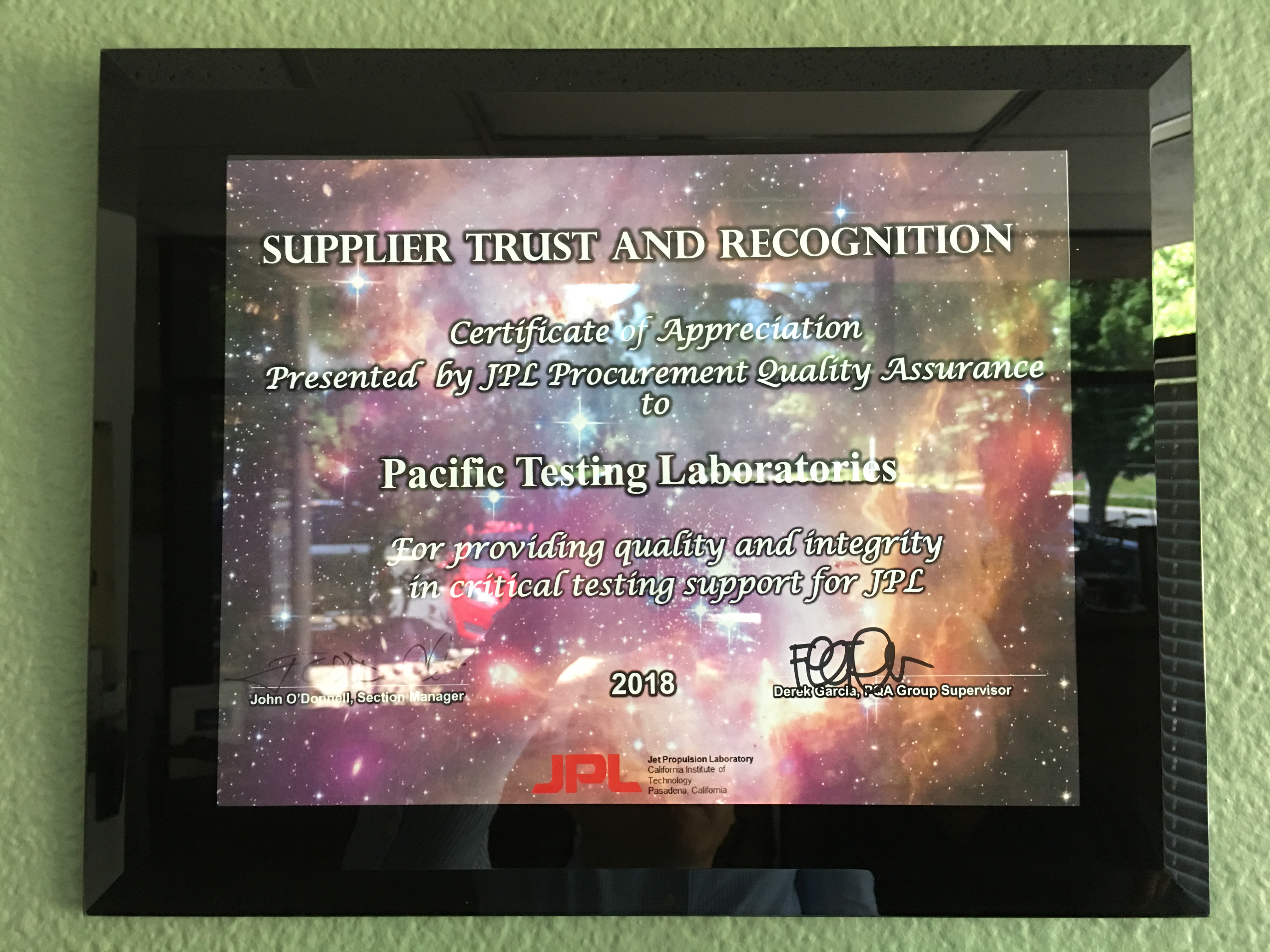

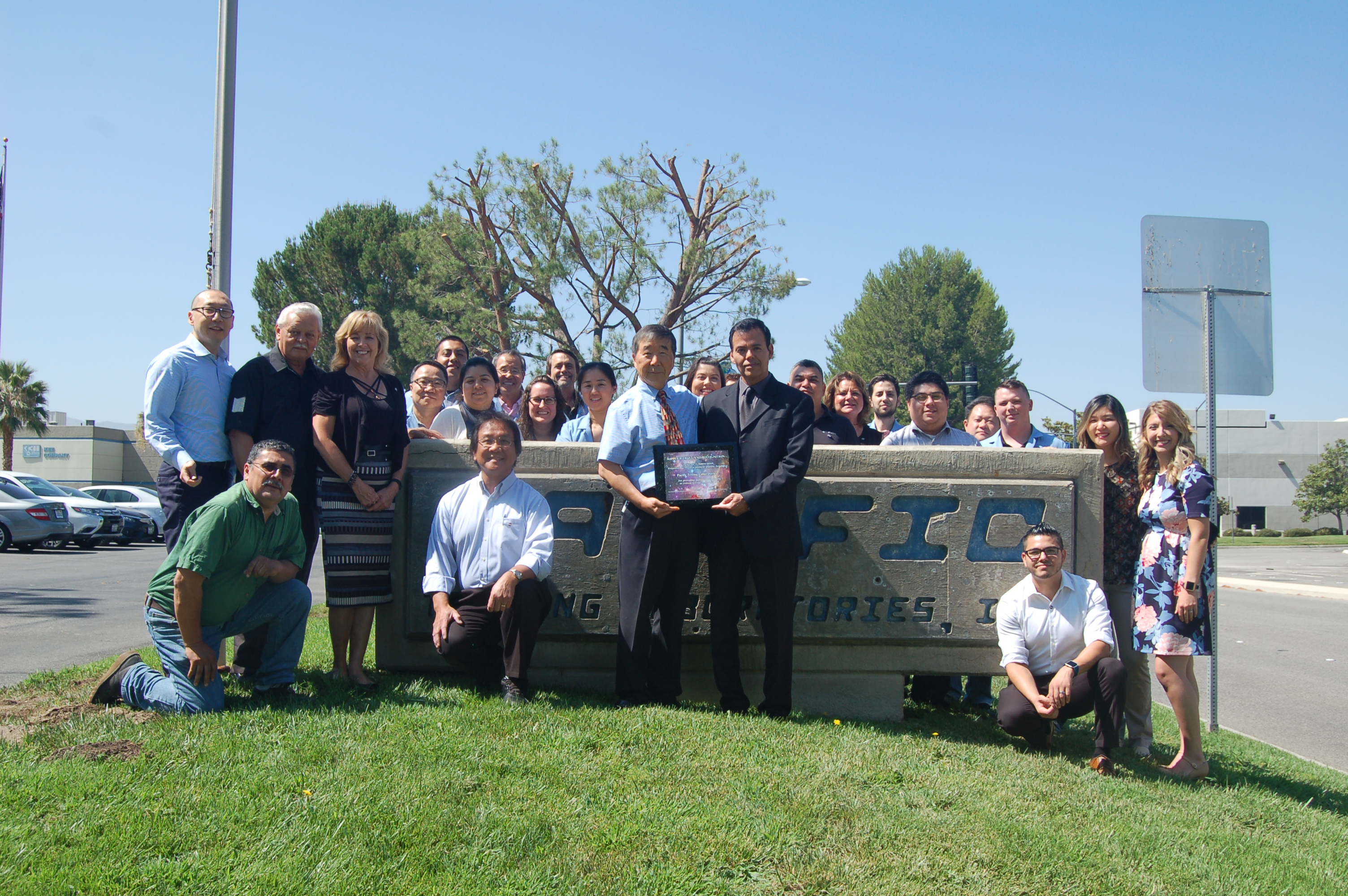

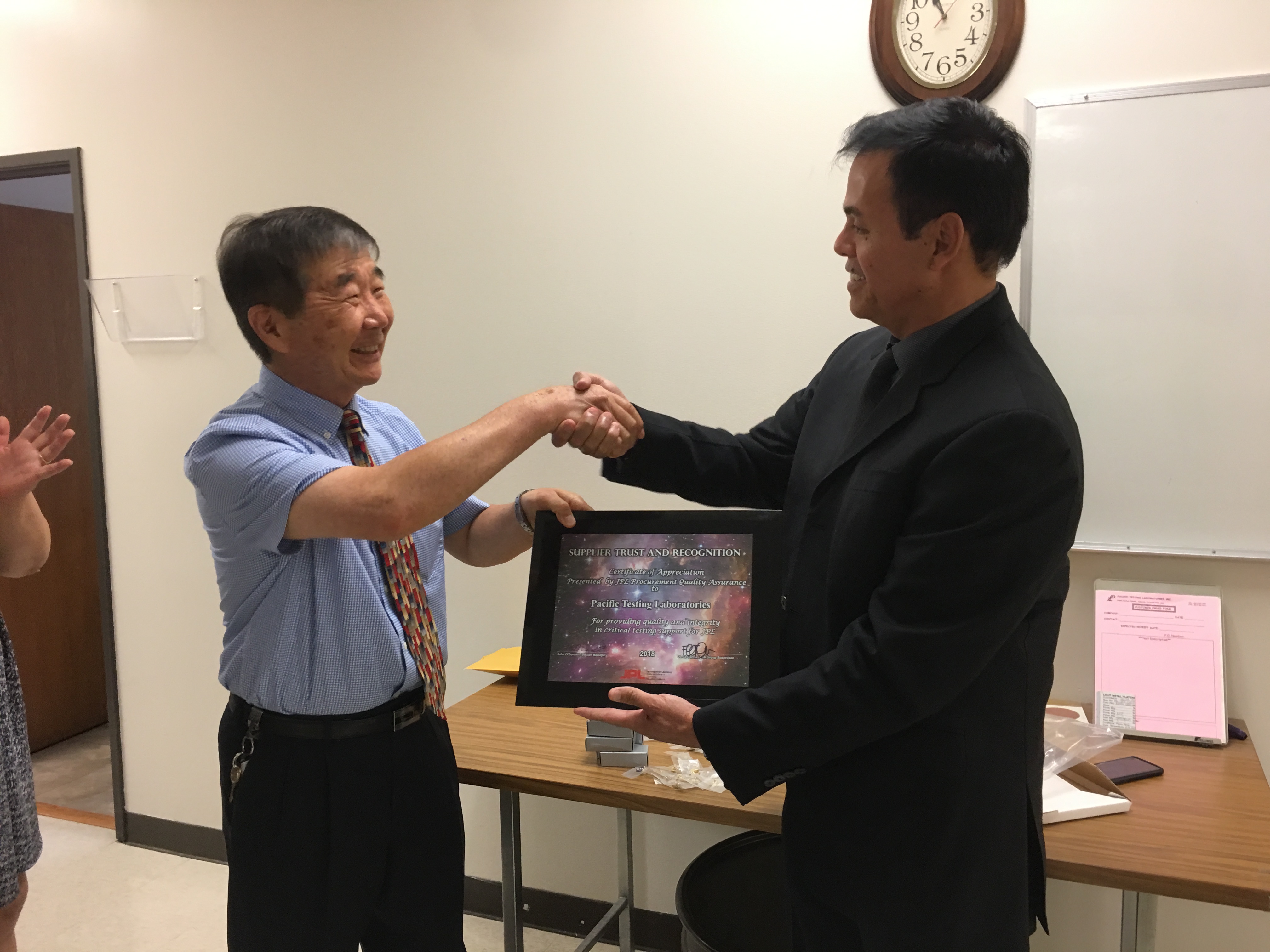

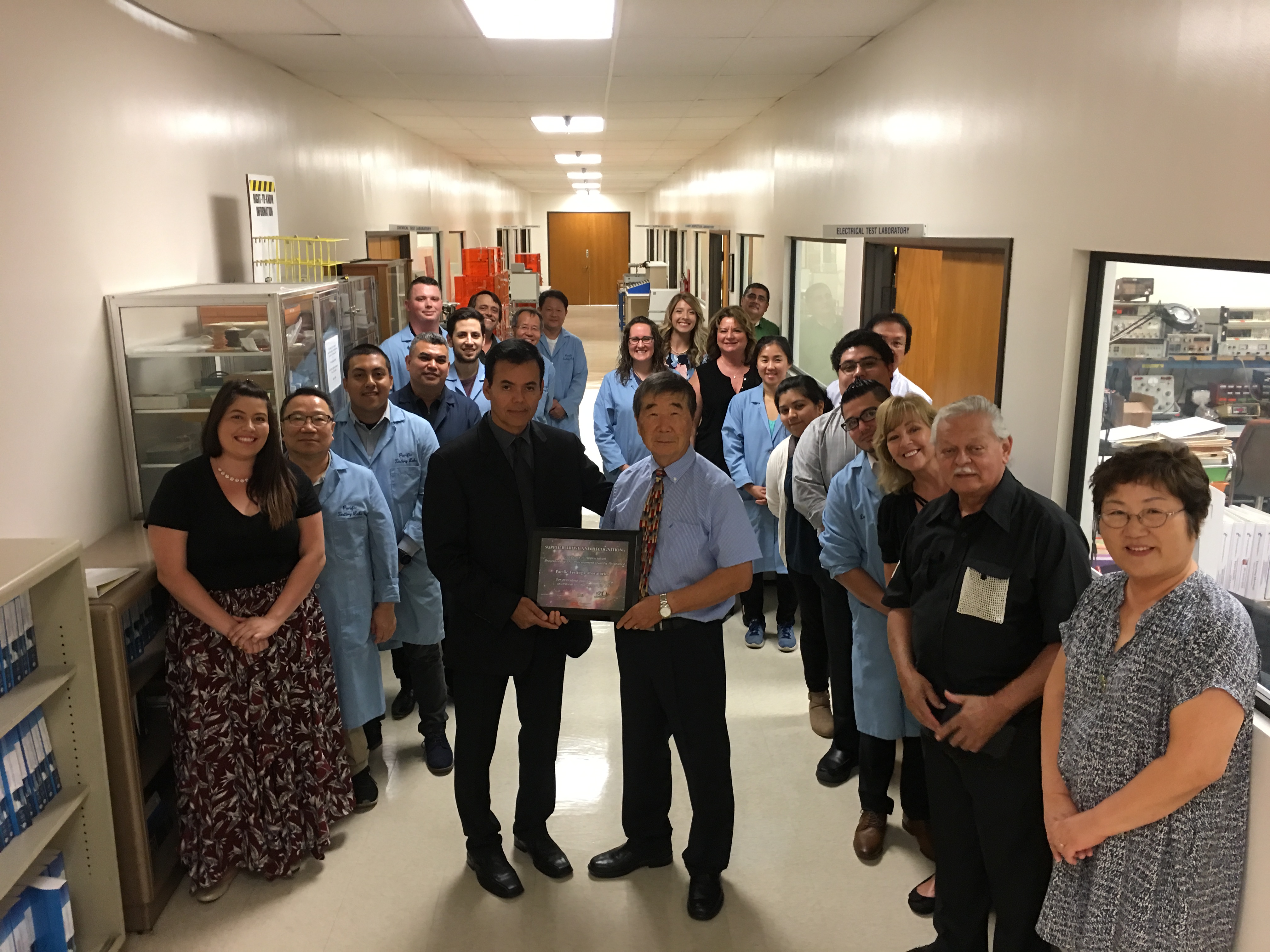

PTL Receives Award

PTL is pleased to announce that it recently received a Supplier Trust and Recognition Award from Jet Propulsion Laboratory (JPL). The Certificate of Appreciate was presented by JPL’s Procurement Quality Assurance, for providing quality and integrity in critical testing support for JPL.

Scanning Electron Microscopy/Energy Dispersive X-Ray analysis (SEM/EDS)

Featuring PTL’s new SEM/EDS system, currently utilized for applications involving Failure Analysis, high magnification imaging, and elemental characterization: JEOL JSM-IT500 InTouchScope Scanning Electron Microscope (SEM) equipped with a Thermo Scientific UltraDry EDS Detector and Pathfinder X-Ray Microanalysis Software for Energy Dispersive X-Ray (EDS) analysis. A few major highlights of the instrumentation include examination in both high vacuum and low vacuum modes, a large specimen chamber, light element sensitivity down to beryllium, spectral imaging, and linescans.

Featuring PTL’s new SEM/EDS system, currently utilized for applications involving Failure Analysis, high magnification imaging, and elemental characterization: JEOL JSM-IT500 InTouchScope Scanning Electron Microscope (SEM) equipped with a Thermo Scientific UltraDry EDS Detector and Pathfinder X-Ray Microanalysis Software for Energy Dispersive X-Ray (EDS) analysis. A few major highlights of the instrumentation include examination in both high vacuum and low vacuum modes, a large specimen chamber, light element sensitivity down to beryllium, spectral imaging, and linescans.

ITAR Registration

Pacific Testing Laboratories, Inc. has completed the International Traffic in Arms Regulations (ITAR) registration process with the U.S. Department of State, Directorate of Defense Trade Controls (DDTC). ITAR compliance will allow Pacific Testing to better serve our Customers, in support of their current and future needs.

Vibration and Shock

To enhance and increase its Vibration and Impact Shock capabilities, Pacific Testing Laboratories has recently added an Unholtz-Dickie Model SAB15F-S202-LP intermediate range Vibration System.

Vibration Shaker and Control Amplifier

The performance of this Vibration System supports a wide variety of Vibration and Impact Shock capabilities, at g levels and weight-handling levels not previously available at Pacific. Applications include product development, design conformance, qualification, certification, and production screening to Military, Aerospace, Automotive, and Medical specifications.

The System is capable of performing to a variety of Test Methods, which may be found in MIL-STD-202, MIL-STD-810, MIL-STD-750, FED‑STD‑101C, or ISO 5344: 2004, etc.

The salient characteristics of the System are a usable Frequency Range of DC to 3500Hz; 100g peak positive and negative maximum Shock Pulse @ 18 pounds; 100g peak maximum Acceleration for Sine Vibration; 70g peak maximum Acceleration for Random Vibration; 2.0 inch displacement; 2500Hz Armature Resonance; Automatic Armature Centering; Isolation Mounting; ESD compatible, etc.

Control Room

The System is under control of a Vwin II Controller, which controls the entire Vibration or Shock program from inside the workstation. The Controller features an Automated Calibration Kit, for Self-Test with an NIST-Certificate; it generates an MS Word report, on command. Typical programs are Random; Sine, both swept and fixed; Resonance Dwell; Classical Shock Pulse, etc.

The Test Engineer maintains full visibility over the Test Program at all times from his position in the Control Room; he is able to continuously monitor the vibration or shock levels, frequencies, sweep count, etc. In addition, the test engineer can immediately abort the test program in the event of an equipment or Test Sample failure.